Everactive Sensors

Everactive Sensors, Supported by Steam Solutions

A complete, around-the-clock steam trap and pump monitoring system is now possible. Steam Solutions is proud to represent Everactive and their line of high-precision steam trap and pump sensor systems.

Full-scope steam equipment monitoring powered by Everactive gives facility managers, process engineers, and plant maintenance professionals a sole source of real-time steam trap and pump health delivered right to your existing PLC or DCS system.

Now, you can optimize resources, reduce heat waste, tackle decarbonization, and stay ahead of equipment failure with the power of always-on monitoring that easily integrates with your existing automation system.

Why Everactive?

Traditional steam equipment maintenance involves manual inspections or the use of battery-powered sensors to monitor a small number of traps or pumps. These approaches can be time-intensive, and they rarely provide an accurate picture of the true health of your steam system at any given time.

With an Everactive system installed and supported by Steam Solutions, you get a 24/7, holistic view of your entire steam system with performance metrics that can alert you to areas where attention is needed to prevent failures and maximize uptime.

Features include:

- Compatibility with all steam traps and pumps, regardless of size, style, or age

- Integration with Armstrong’s SAGE platform

- Email and text alerts and notifications

- Class 1, Division 2 UL-listed, IP66-rated hardware

- Fully autonomous, battery-free sensors harvest energy from ambient heat sources

For Steam Traps

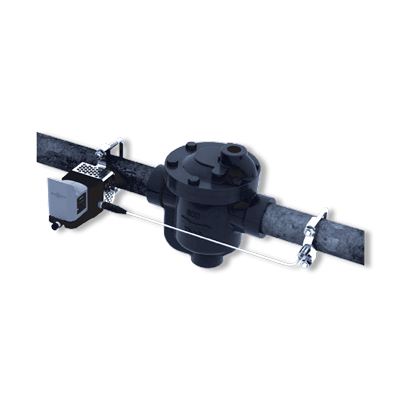

Everactive steam trap sensors are placed before and after the steam trap, and each Eversensor wirelessly transmits condensate, steam, and ambient temperature readings at configurable intervals.

Email or text alerts are sent immediately upon detection of alarm conditions. This puts you in front of impending trap failures and keeps you informed on the operating condition of your steam traps via integration with Armstrong’s SAGE platform.

For Pumps

Everactive’s Machine Health Monitoring (MHM) system was designed to continuously gauge the performance of rotating equipment like motors, pumps, fans, and compressors.

When Everactive sensors are installed on opposing ends of a pump, they transmit vibration, temperature, and magnetic field data back to a wireless gateway. There, the data is aggregated and served up to the PLC or DCS system for analysis.

See the Benefits for Yourself with a Demo

When the performance data of your steam equipment is continuously provided directly to you, you save time and money. And, when you have Steam Solutions available to you for service, support, and help with system expansion, you get peace of mind, as well.

The future of steam equipment monitoring is here, and we are ready to bring it to your plant.

To learn more, see a demo, or get a quote, contact us today.

You know your business. We know how to make sure you stay ahead.

Every heat transfer system has a story. We’re ready to learn yours and to do everything we can to make sure it performs at its absolute peak potential. Contact our team to learn more.